Trial Magazine

Theme Article

Revealing Seat Defects

When representing a client who was injured in a vehicle crash, be aware of the role seatback and headrest defects can play in increasing the severity of injuries.

November 2022Imagine gradually stopping in a line of highway traffic, glancing up at your rearview mirror, and seeing that a car behind you is not slowing down. There is no time to do anything but helplessly brace for impact. The safety device that will determine your fate—and the fate of anyone sitting behind you—is your front seat. If the front seat is sufficiently strong and adequately designed, you may walk away with just temporary inconvenience and soreness. A weak and defective seat, however, increases the risk of a life-altering traumatic brain injury (TBI) or spinal injury. Sadly, defective seats and headrests needlessly continue to harm vehicle occupants.

Dangers Posed by Defective Seats

In frontal collisions, seat belts and air bags protect occupants by keeping the occupant in the seat and limiting dangerous contacts with the passenger cabin and debris. Similarly, in rear-end impacts, the front seat’s role is to manage energy and contain the occupant in the front seating space.1 Weak, defective front seats, however, can fail, collapse, and cause front occupants to catapult backward into the rear of the vehicle. This creates a dangerous hazard to both the front occupant and those sitting in the back.

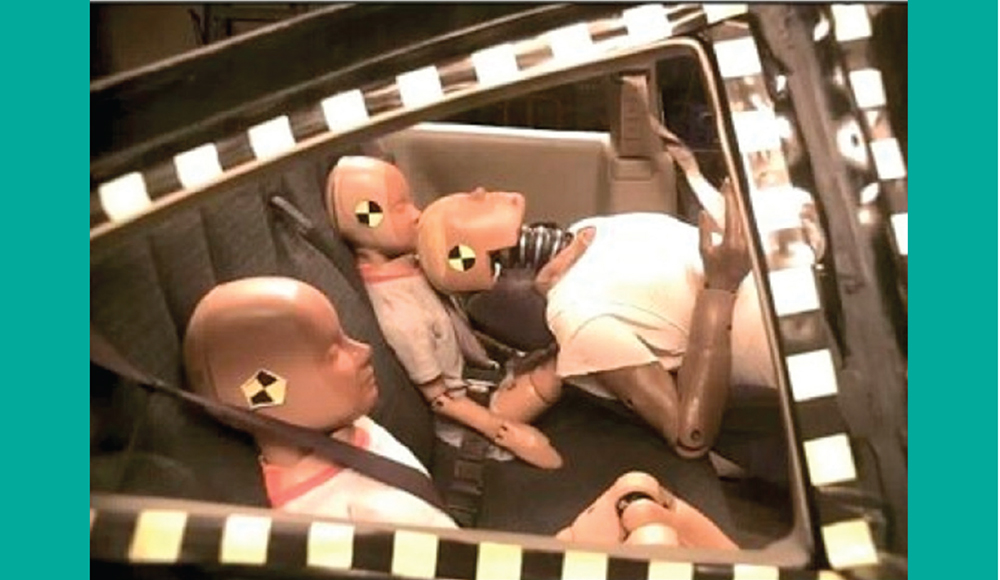

Danger to children. Over a 24-year period, nearly 900 children seated behind front seat occupants were killed in rear impacts.2 Countless others have suffered severe brain injuries. Auto manufacturers typically recommend that children 12 and younger be seated in the back to avoid injuries from air bag deployments, but they do not warn parents that the front seats may fail and put their children in danger. When front occupants catapult rearward in a seatback failure, children in the back seat may suffer severe TBIs.

Seat failure causes dangerous contact with rear child.

Copyright © 2022 Langdon & Emison Attorneys at Law

Danger to front occupants. Seatback failures pose a potentially lethal danger to front occupants in two common scenarios. First, front occupants risk severe spinal and brain injuries as their bodies jettison into the rear of the vehicle and violently contact a rear occupant or the rear seat. Second, an initial rear-end impact may leave a front occupant out of position in the seat and vulnerable to being thrown around within the vehicle in subsequent impacts.

Seat failure causes dangerous contact with rear seat.

Copyright © 2022 Langdon & Emison Attorneys at Law

Signs of Defective Seats and Headrests

If you suspect a seat failure led to or increased the severity of your client’s injury, start by determining the mechanism of injury. A biomechanical expert can use the physical evidence, mechanism of the seatback failure, and evidence of injuries to determine the forces that ultimately caused the enhanced injuries. It also is important to identify deformation to the seat and evidence of occupant contact with other structures. Every rear-end collision that involves a serious TBI, spinal injury, or death should be screened for defective front seats. There are several telltale signs of a seat failure.

Deformed or twisted seats. In seatback failures, the front seat commonly appears deformed or twisted. While visible deformation is a red flag, deformation is not always visible. A defective seat may collapse and absorb a small amount of energy. In such a case, there will be less deformation. When there is little visible seat deformation, the key to identifying a seat failure is first identifying a severe brain or spinal injury in a rear impact.

In addition, during the investigation process, the front seat may not always be reclined rearward after a failure. First responders or scene witnesses commonly adjust the seats in the extrication process. Interview them about their observations of the seat and your client after the impact.

Head and facial trauma. Trauma to both the front and rear occupants provides clues as to whether a defective front seating system contributed to enhanced injuries. Rear occupants may have severe TBIs, facial fractures, or head lacerations. Lacerations, contusions, and injuries to the back or top of a front occupant’s head also provide evidence that the front occupant ramped (slid up the seat) rearward and struck a rear occupant. And the friction from rapidly ramping rearward in a seatback failure has been known to cause occupants to lose streaks of hair, which provides evidence of a seatback failure.

For example, in one case, a child was seated in the back behind her mother when their vehicle was struck. The front seat did not contain the mother in the front—rather the mother ramped rearward, striking the child. The child suffered frontal skull and orbital fractures that resulted in severe traumatic brain injuries. The mother suffered less severe injuries, but a 3-inch laceration on the back of her head provided key evidence that she ramped rearward and struck her child due to her defective seat.

Signs of contact on the rear seat. When a defective seat allows a front occupant to catapult into the rear seat, there may be evidence of the contact on the rear seat. For instance, in a recent case, a front occupant ramped into the rear of the vehicle and suffered a catastrophic spinal injury. Documentation of his hair on the rear seat provided key evidence of the front seat failure and subsequent ramping into the rear seat.

Broken or missing headrests. Look for a missing or broken headrest. To dislodge or break the headrest, an occupant’s body must ramp rearward and load (apply force to) the headrest. A broken headrest shows the seat did not properly contain the occupant. Injuries resulting from headrest failure include paraplegia.

Failure Modes

The exact failure mode in a seatback is difficult to determine until the seat is “detrimmed.”3 This involves removing the cushioning to reveal the structure of the seat and its components. To detrim a seat, an expert engineer retained by the plaintiff typically develops a protocol with the manufacturer’s retained engineers. (See below for an example of the internal seat components.)

Copyright © 2022 Langdon & Emison Attorneys at Law

Recliner failures. This mechanism adjusts the seatback and may be a single recliner or, as in most seats manufacturered over the past 10–15 years, a dual recliner (on both sides of the seat). When a recliner fails, the seating system as a whole dangerously collapses. In a single-recliner design, the side that does not have a recliner provides no rearward resistance. In a rear-end impact, this may cause the seatback to deform rearward and also to twist and throw the occupant rearward toward the center of the rear seat.

Some defective seating designs are susceptible to inadvertent unlatching of one or both recliners during a rear-end event. In this failure mode, dynamic forces lead the seat to disengage the recliner mechanism, which then causes the seat to collapse rearward while absorbing little or no energy.

When a complete or partial collapse occurs, the seat frame will have very little deformation and bending. In these situations, consider potential failure modes of the recliner and scenarios that allow an occupant to move out of the seat during a collision event.

Headrest failures. In recent years, seats generally have become stronger. As seats become stronger, the failure mode in some seats has shifted to the headrest. If a headrest is broken or pulled out in a rear-end impact, investigate a possible failure.

The auto industry has known about the importance of headrests and the danger of failures for decades. Rear crash testing in the 1960s of seats without headrests showed occupants faced a high risk of spinal injuries and led researchers to conclude that “head restraints are as important to the motorist involved in rear-end collisions as the safety belt is to the motorist involved in a front-end impact.”4

The headrest should be designed in conjunction with the seatback to support the occupant and prevent the occupant from ramping. When a seat yields rearward and a front occupant loads the headrest, weak and defective headrests may pull out or break. This creates a dangerous situation in which the front occupant’s spine hyperextends over the top of the seatback, which may cause paraplegia. (See below for an examle.)

Headrest failure causes spine to hyperextend over the top of the seat.

Copyright © 2022 Langdon & Emison Attorneys at Law

Failure to contain front occupant. Also keep in mind that a seatback does not have to break to be a “failure.” Although a part may break in a seatback failure, many failures have no actual broken parts. The failure is the seating system’s inability to safely contain an occupant in the front occupant space. Weak seats may be elastic, rapidly yield rearward, and expose occupants to injury regardless of whether a part breaks. The key to identifying these cases is the injuries to the occupants—namely catastrophic spine and brain injuries.

Litigating Defective Seat Cases

In a defective seat case, we typically sue the automobile manufacturer and seat manufacturer. The roles of each of these manufacturers vary from case to case, but we’ve found they often work together to develop the seat. Commonly, a seat manufacturer performs the seat-level testing (such as sled tests solely involving a seat and dummy), whereas the auto manufacturer performs vehicle-level testing (such as barrier tests that impact a completed vehicle).

Seat manufacturers tend to be huge, sophisticated corporations that boast the ability to produce a vehicle seat from concept through the production process—and they may have key documents that the auto manufacturer claims it does not possess.

Here are some documents that you should request in nearly any seatback case from both manufacturers:

- seat performance standards

- statement of work (outlines the seat design project and roles and responsibilities)

- design verification plan and report (describes applicable performance standards and testing results)

- rearward testing (including Federal Motor Vehicle Safety Standard (FMVSS) 301 tests, sled tests, and pull tests)5

- failure mode and effects analyses

- deviations (ignoring failed tests to approve a seat).

Other similar incidents. Often, your client’s seatback failure is not the first, so request information on other incidents in discovery from the defendants. In addition, search the National Highway Traffic Safety Administration’s (NHTSA) Fatality Analysis Reporting System (FARS) and National Automotive Sampling System (NASS) for prior incidents. In jurisdictions that allow evidence of other similar incidents, this data can provide powerful evidence of the manufacturers’ notice of dangerous seat failures.

Common Defenses

When asserting a seatback failure claim against auto and seat manufacturers, expect them to raise certain defenses.

Federal standards. In nearly every rear-impact seat case, the manufacturer will tout that the seat passed the minimum federal standard for rearward seat strength, FMVSS 207.6 However, as minimum federal safety standards have improved in other areas of automotive safety over the past 50 years, seatback safety has not. Federal standards for rearward seatback strength have not changed since the 1960s.7 The present standard involves a pull test of an unoccupied seat that is so inadequate a lawn chair can pass.8 In real-world crashes, seats must withstand dynamic forces and manage the weight of human occupants. Tests pursuant to federal standards do not mimic realistic conditions.

Because FMVSS 207 does not reflect how a front seat will perform in a real-world collision, safety advocates have asked the federal government to increase front seat safety standards for years. NHTSA has acknowledged that the minimum federal standard is inadequate.9 Despite this, multiple petitions to improve the standards have failed—auto manufacturers have repeatedly lobbied against updated standards.

There is now reason to hope for change. Last year, Congress passed the Infrastructure Investment and Jobs Act of 2021, tasking regulators with updating seatback safety standards within two years after the law’s enactment.10 While this is progress, the end result is still uncertain.

Severity of the impact. The manufacturers’ primary defense is the severity of the collision. In virtually every case, the manufacturer argues the crash was so severe the seat could not protect the occupant, and it attempts to place the sole blame on the at-fault striking driver. Manufacturers know a significant number of their vehicles will be involved in rear-end impacts, ranging from residential to highway speeds. The federal government requires vehicles to pass FMVSS 301R,11 a rear-impact barrier test typically run at 50–55 mph. Although it is a fuel integrity test, it exemplifies that vehicles must be crashworthy at highway speeds. These collisions are foreseeable and should not result in catastrophic injuries.

Danger of stronger seats. Manufacturers also claim that strong seats put front occupants at increased risk of whiplash injury in low-severity collisions. This has been addressed with the advent of active headrests that reduce the risk of whiplash injuries in low-speed impacts. In a rear collision, an active headrest moves forward and upward to limit the backward movement of the occupant’s head and thus reduce the risk and severity of whiplash.

When the head and body are properly supported, the human body can withstand significant forces from the rear direction.12 If seats are designed to support and contain occupants, they can withstand significant rearward forces.13 If seatbacks fail, occupants are subject to catastrophic injuries or death.14

Unsafe front seats continue to cause incalculable harm. If a front or rear occupant suffers a catastrophic brain or spinal injury in a rear impact, investigate whether a defective seat or headrest contributed to the severe injuries. Recognizing the common red flags of a seat or headrest failure will help you to hold manufacturers accountable—and motivate them to improve vehicle safety.15

Bob Langdon and Mark Emison are partners at Langdon & Emison with offices in Lexington, Mo.; Kansas City; St. Louis; and Chicago, and they can be reached at bob@lelaw.com and mark@lelaw.com, respectively.

Notes

- Derwyn M. Severy et al., Designing Safer Seats, 84 Auto. Eng’r 10 (Oct. 1976).

- Ctr. for Auto Safety, NHTSA Urged to Warn Parents of Seat Back Failure Dangers to Children in Rear Seats, Mar. 9, 2016, https://www.autosafety.org/nhtsa-urged-to-warn-parents-of-seat-back-failure-dangers-to-children-in-rear-seats/.

- To better understand the dynamics of a seatback failure, please visit the website in note 15 to watch crash-test videos and read analytical articles on safe seat design.

- Derwyn M. Severy, Harrison M. Brink, & Jack D. Baird, Backrest and Head Restraint Design for Rear-End Collision Protection, 1968 Auto. Eng’g Congress & Exposition (1968).

- FMVSS 301R is a fuel integrity barrier impact test. Rear-impact FMVSS 301 testing provides valuable information to show how a seat performs in a rear impact. These tests are typically run at 50+ mph. In a rear sled test, rearward forces are applied to the seat and dummy occupant. Pull tests are static, unoccupied testing that typically reflect the FMVSS 207 standards.

- 49 C.F.R. §571.207 (West 2022).

- Letter From Sens. Edward J. Markey & Richard Blumenthal to General Motors CEO Mary T. Barra (May 25, 2016), https://www.markey.senate.gov/imo/media/doc/FMVSS%20207_GM.pdf.

- Letter From Alan Cantor, ARCCA, to NHTSA Administrator (Sept. 28, 2015), https://tinyurl.com/ypcwv4xr.

- Press Release, Nat’l Hwy. & Traffic Safety Admin., B.01.19 Seat Back Strength (Dec. 1998) (“There have been several valid criticisms of the current Federal Motor Vehicle Safety Standard No. 207 which addresses seating systems. Generally it is acknowledged that the current standard requires inadequate seat strength to insure that the seat does not fail when a car is subject to a severe rear impact.”).

- Pub. L. No. 117-58 (2021).

- 9 C.F.R. §571.301 (West 2022).

- For more on the human body’s ability to withstand rearward force, see Smithsonian Nat’l Air & Space Museum, The Man Behind High-Speed Safety Standards, Aug. 22, 2018, https://airandspace.si.edu/stories/editorial/man-behind-high-speed-safety-standards. In the 1950s, Air Force Col. John Stapp put this to the test in studies of acceleration and deceleration forces on humans in an effort to advance the science of high-speed aircraft. In testing on a rocket sled, he reached a speed of over 600 mph and experienced G forces above 40. This demonstrated the extreme rearward forces the human body can tolerate. Col. Stapp’s pioneering research spilled over into automobile safety and influenced many of the safety features in vehicles today.

- Id.; Severy et al., supra note 1.

- Kenneth J. Saczalski et al., Study of Seat System Performance Related to Injury of Rear Seated Children and Infants in Rear Impacts, ASME 2002 Int’l Mech. Eng’g Congress & Exposition (Nov. 2002).

- For helpful links on car seat safety, including crash-test videos and analytical articles on safe seat design, visit www.langdonemison.com/car-seat-defects-resource-center.